Jiangsu gewabin heat technology Co,.Ltd

Jiangsu gewabin heat technology Co,.Ltd

Compact structure, small footprint. Especially suitable for low temperature or small temperature difference between the fluid cooling.

Introduction

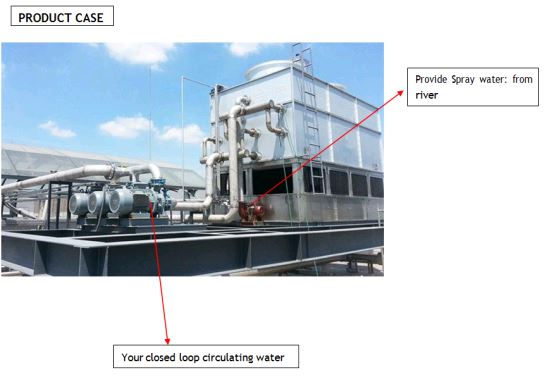

Energy Saving Closed Cooling Tower is the bottom counter current, and the saturated warm air is formed with the falling water spray water, the heat is discharged from the top air blower, then the water is recycled by the dehydrator of special structure. Internal space without pre-cooling of the filler, more space to increase the unit heat radiation area, compact structure, small footprint. Especially suitable for low temperature or small temperature difference between the fluid cooling.

Structure and main parts

1.Condensing Coil

1) Made of high-quality seamless steel pipes. The coil unit are made by SS-304/316L stainless steel. Maximum pressure of our coils could reach to 32Mpa.

2) Special tube arrangement ensure a smarter size and high heat-exchange rate. All tubes are tested at 2.5MPa air pressure

3)Special oval tube ensure a better contacting of water on the outer surface of the tubes

2.Axial Fan

1) Low noise with large air-flow

2) Aluminum alloy blades

3) Damp-proof motor

4) One piece molded heavy duty construction

3.Water Pump

1)Low noise & Large water flow

2)Protection level IP55, Insulation level F

3)Trouble-free operation

4.Water Distribution System

GWB cooling water spray system adopts large discharge and anti-blockage nozzles,which can ensure the cooling ater furthest contact the condensing coil and hence overcome the fouling and promote the moisture to vaporize,thus improve the effect of heat transfer.

5. Removable Drift Eliminator

1)Material:specially designed non-corroding PVC

2)Advantage:remove moisture effectively from the moist air .It ia convenient to disassemble.

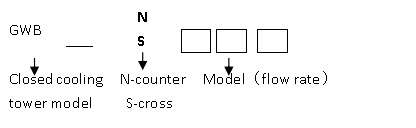

Selection guide

1.The cooling water flow G=m3/h

2.Thetempeatue of inlet coling tower T1=℃

3.The tempeatue of outlet coling tower T2=℃

4.The calculation wet bulb temperature of installation location T=℃

The heat rejction calculation od closed cooling tower

Q=1.163xGx(T1-T2)

Advantage

1. Combination Closer approach to wet bulb temperature and reduce fouling improve process efficiency

2. Lower process temperatures ,less required space ,and lower energy consumption.

3. Through Systems Reduces environmental impact ,saving up to 95% of the cooling water .

4. Reduced installed Cost And Space Requirements Effectively combines the function of a cooling tower and heat exchanger into one piece of equipment ,reduce required piping and system complexity.

Hot Tags: energy saving closed cooling tower, suppliers, manufacturers, customized, price, Industrial cooling towers manufacturers, Cooling Towers and Evaporative Condensers manufacturers, Cross Flow Closed Circuit Cooling Tower, KHC Closed circuit type cooling tower, Dry Cooling Tower factory, Cooling Towers and Evaporative Condensers pric