Advantages Of Evaporative Condenser In Air Conditioning Refrigeration System

In recent years, China has applied evaporative condensers to various refrigeration systems, including cold storage, central air conditioning, industrial refrigeration units, ammonia refrigeration systems, etc. As early as the 1970s, developed countries began to replace water-cooled condensers with evaporative condensers.

Compared with traditional condensers, evaporative condensers have the following advantages:

1.Energy saving

Same as air-cooled condenser, the condensing capacity is limited by the ambient dry bulb temperature, while the evaporative condenser is limited by the ambient wet bulb temperature, and the wet bulb temperature is 8 ~ 14 ℃ lower than the ordinary dry bulb temperature, plus the upper fan The negative pressure environment caused to the equipment, compared with the air-cooled condenser, the evaporative condenser has a lower condensation temperature. And each time the condensation temperature rises by 1 ° C, the power consumption per unit of cooling capacity will increase by 3% to 3.5%, so the total power consumption of the evaporative condenser will be significantly reduced, and the energy saving effect will be obvious. Compared with other condensers, it can save 20% to 40% in air-conditioning refrigeration systems.

2.Water saving

Evaporative condensers make full use of the latent heat of vaporization of water. General water-cooled condensers can take away 16.75 ~ 25.12KJ of heat per 1Kg of cooling water, and 1Kg of water can take away about 2428KJ of heat at normal temperature. Therefore, the theory of evaporative condensers The water consumption is only 1% of the water-cooled condenser. Taking into account factors such as splash loss, sewage and water exchange, the actual water consumption is about 5% to 10% of the water-cooled condenser.

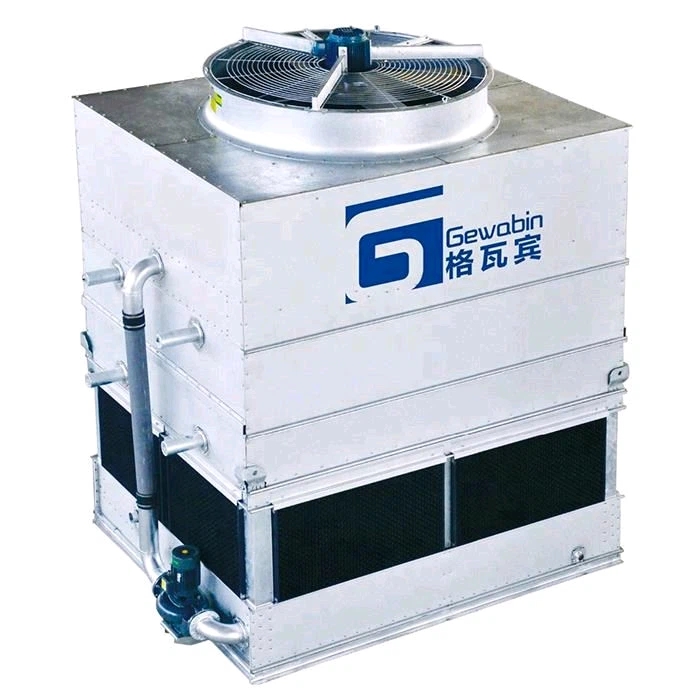

3.The structure is compact

Because there is no need to set a cooling tower, the entire device has a compact structure, small size and small footprint. The evaporative condenser saves valuable space by combining the condenser coil and the cooling tower into one, and there is no need to provide the cooling tower / Condenser systems require larger pumps and piping. Evaporative condensers require only about 50% of the windward area of air-cooled condensers of the same specification.

4.Cost saving

Evaporative condensers integrate cooling towers, condensers, circulating pools, circulating water pumps, and water pipes into one unit. This reduces equipment such as cooling towers, circulating water pumps, and water pipes. It also reduces processing and installation of individual components in the cooling tower / condenser system. cost of. Since the evaporative condenser uses the evaporative cooling and heat exchange method efficiently, it can effectively reduce the heat exchange area, the number of fans, and the power consumption of the fan motor.

5. environmental protection

Many chemical plants used shell-and-tube or irrigated condensers in the past. Because of the high condensing pressure in summer, "venting and depressurizing" is often used, but each time it is not a non-condensable gas, which contains a large amount of ammonia. According to sampling analysis by relevant departments, sometimes as high as 90%, not only the ammonia loss is quite serious, but also environmental pollution. But this phenomenon does not exist after using the evaporative condenser.