Jiangsu gewabin heat technology Co,.Ltd

Jiangsu gewabin heat technology Co,.Ltd

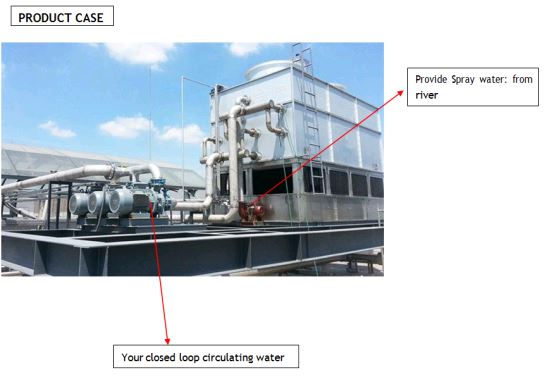

A circulatory system that avoids the direct contact of circulating water and air and causes water pollution.

Cooling tower closed loop system Introduction

A circulatory system that avoids the direct contact of circulating water and air and causes water pollution. This circulation system is an automatic variable frequency control system. Greatly save electricity and water. Counterflow closed cooling tower.

| Main Components | |

| Coil | Made of high-quality seamless steel pipes. The coil unit are made by SS-304/316L stainless steel. Maximum pressure of our coils could reach to 32Mpa. |

| Spray Pump | Sealed by top quality rotary no-limited machinery seal, no leaking, long lifecycle, small horse power, large flow volume, low noise and high performance. |

| Fan | Axial type;aluminum alloy propeller |

| Casing | SS-304/316L or imported Aluminum-zinc alloy plate, Mg-Al-zinc plate |

| Electric Water Treatment Device | Clear the circuit water, effectively avoid the scale forming on the surface of coils and PVC fills. |

| Removable Drift Eliminator | PVC material; Make sure that the water loss rate will be less than 0.002% |

| Air inet louver | 100% Original Material PVC Infill, special design with great cooling effect |

Features of cooling tower closed loop system

Compatible with numerous process fluids

(water, water/glycol, oil, other fluids)

Ø Capable and flexible in customized solutions

Ø Factory assembled for maximal installation convenience

Ø Modular design suits a wide range of heat rejection duties

Ø Compact design with minimal footprints

Ø Multiple corrosion resistant options

Ø Low sound operation options available

Ø More optimizing options available

Ø Performance and quality guaranteed

Ø Super long service life

Maintenance

Since the process fluid of a closed loop system is completely isolated from the environment, routine maintenance is only required on the heat rejection equipment itself. The need to shut down the system periodically to clean the heat exchanger is dramatically reduced, if not entirely eliminated. Providing clean process fluid to the system will extend the life of other components in the system (condenser bundles, compressors, etc.).

Water Treatment

Maintaining proper process fluid quality in a system may involve several steps, such as chemical treatment, filtration equipment and the addition of clean make-up water. A closed circuit cooling tower can provide the following advantages over an open cooling tower:

Lower volume of recirculating water to treat.

Process loop requires minimal treatment.

During periods of dry operation, the need for make-up water is eliminated.

Our service

For new and old import and export customer supply:

1.A professional sales team, experienced engineers, advanced manufacturing equipment, particular production technology;

2.Strictly implements ISO9001 Standard in all pretation; CE quality

guarantee system keep and assure customer products and delivery time.

3.Supply specialized installation guidance and after services that anytime and any country if customer need.

4.Reply your inquires within 24 hours anytime and anywhere.

Customer need is the most important; Customer benefit is our benefit; Our grow from company credit and working duty for our new and old customers.

Hot Tags: cooling tower closed loop system, suppliers, manufacturers, customized, price, OEM Water cooling tower system, Water Cooling Tower factory, closed circuit Cooling tower philippines, Counter Flow Square Cooling Tower, OEM Cooling Towers And Adiabatic Fluid Coolers, Metal Closed Type Cooling Tower