Jiangsu gewabin heat technology Co,.Ltd

Jiangsu gewabin heat technology Co,.Ltd

The closed cooling tower will be exchanged by the cooling medium through the coil and the cooling water and air outside the tube to form a closed circulation system, which avoids the pollution caused by the contact of the cooling medium with the air, thereby causing waste of the cooled medium and equipment. Failures such as blockages affect normal use.

Introduction

The closed cooling tower will be exchanged by the cooling medium through the coil and the cooling water and air outside the tube to form a closed circulation system, which avoids the pollution caused by the contact of the cooling medium with the air, thereby causing waste of the cooled medium and equipment. Failures such as blockages affect normal use.

The structure of the cooler is of the coil type and the tube box type.

Features

1. The cooling medium is completely closed to prevent debris from entering the cooling pipeline system and the evaporation loss of the cooling medium.

2. Use soft water as cooling medium, no scaling, no clogging of pipelines, and few failures.

3. The dual cooling method of air cooling and spray water evaporation heat absorption is adopted, and the cooling efficiency is high.

4. The device is small in size, takes up little space, and is easy to move and place, without the need to build a pool.

5. Using automatic intelligent control, it can automatically change the cooling mode according to the requirements of working conditions, and the operation is simple and reliable.

6. Widely used, it can directly cool the quenching fluid, oil, alcohol and other media that have no corrosive effect on the heat exchanger. The media has no loss and the composition is stable.

| Main Components | |

| Coil | Made of high-quality seamless steel pipes. The coil unit are made by SS-304/316L stainless steel. Maximum pressure of our coils could reach to 32Mpa. |

| Spray Pump | Sealed by top quality rotary no-limited machinery seal, no leaking, long lifecycle, small horse power, large flow volume, low noise and high performance. |

| Fan | Axial type;aluminum alloy propeller |

| Casing | SS-304/316L or imported Aluminum-zinc alloy plate, Mg-Al-zinc plate |

| Electric Water Treatment Device | Clear the circuit water, effectively avoid the scale forming on the surface of coils and PVC fills. |

| Removable Drift Eliminator | PVC material; Make sure that the water loss rate will be less than 0.002% |

| Cooling Tower Fill | 100% Original Material PVC Infill, special design with great cooling effect |

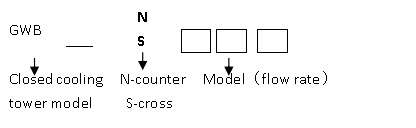

Selection Guide

1.The cooling water flow G=m3/h

2.The temperature of inlet cooling tower T1=℃

3.The temperature of outlet cooling tower T2=℃

4.The calculation wet bulb temperature of installation location T=℃

The heat rejection calculation of closed cooling tower

Q=1.163xGx(T1-T2)

Application

It can be used in air conditioners, instrumentation, metallurgical intermediate frequency electric furnaces, converters, power plant generator sets, steam turbine nuclear power plants, substations, chemical, pharmaceutical, welding, aluminum, copper foil cooling oil, large hydraulic machinery hydraulic oil Used in industrial manufacturing fields.

Maintenance

Cooling tower maintenance at high temperature

Pay attention to the water supply of the closed cooling tower in summer: the temperature increases in summer and the evaporation of spray water is slightly higher than that in winter. Check the water tank and replenish the water regularly.

Check the water distribution of the sprinkler: the closed cooling tower generally adopts the water distribution of the sprinkler. If the nozzle in the cooling tower is partially blocked, or the nozzle falls, it will cause uneven water distribution. To avoid dry spots, regular inspection of the water distribution of the nozzle is essential for the cooling tower.

Cleaning the equipment inlet / outlet: The equipment is operated outdoors for a long period of time. Regular maintenance and inspection of the inlet / outlet are required to remove the obstruction of the inlet / outlet network.

Packing damage: The common problems of packing are scaling and aging. Generally, the cooling tower that has been used for many years will have the problem of filler damage. If the filler is damaged in a large area, it will affect the temperature of the spray water, resulting in a cooling effect. The service life of the packing of the closed cooling tower is generally 7-8 years. They are all produced from raw materials. The above problems are minimal, and the aging packing must be replaced.

Maintenance of cooling tower in rainy season

The closed cooling tower, because partly used in the open air, it is inevitable that rainy water will enter the spray circulating water of the cooling tower in the rainy season. Rainwater mixed with medium sulfur and carbon, etc., falling into the closed cooling tower will cause acidification of the water quality.

The acidified cooling water circulates in the closed cooling tower, and its corrosion rate is as much as 5 times of the normal service life.

If you encounter a lot of rain, it is recommended to replace the spray water to prevent the coil from being corroded by rain.

If less rainwater is mixed into the closed cooling tower, the water quality can be treated by adding medicine to neutralize the water quality.

Hot Tags: closed cooling tower, suppliers, manufacturers, customized, price, Cooling Tower Systems, Closed water Cooling Tower fluid cooler, cross flow type cooling tower, Industrial cooling towers pric, OEM Dry Cooling Tower, Cooling tower in refrigeration system