Jiangsu gewabin heat technology Co,.Ltd

Jiangsu gewabin heat technology Co,.Ltd

ISO certified factories ensure high quality factory assembly.The closed cooling tower originates from the evaporative cooler, but it is actually a heat exchanger that combines the performance of the water-cooled cooler and the conventional cooling tower. It is also a heat exchange between the water cooler and the air cooler device.

Introduction

The closed cooling tower originates from the evaporative cooler, but it is actually a heat exchanger that combines the performance of the water-cooled cooler and the conventional cooling tower. It is also a heat exchange between the water cooler and the air cooler device.

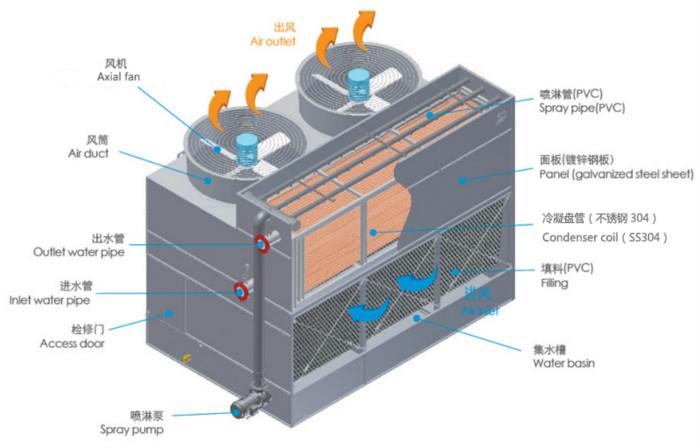

It is characterized by spraying water outside the partition wall heat exchanger and forced ventilation. The heat is transferred from the cooled fluid in the partition wall heat exchanger through the wall surface to the spray water outside the wall surface, and then forced by the spray water and air. Convection is transferred to the air, and the heat transfer from spray water to air is mainly composed of the latent heat of spray water evaporation and the sensible heat exchange between spray water and air. The cooled fluid circulates in a closed manner between the partition wall heat exchanger and the external process equipment.

| Main Components | |

| Condenser Coil | Made of high-quality seamless steel pipes. The coil unit are made by SS-304/316L stainless steel. Maximum pressure of our coils could reach to 32Mpa. |

| Spray Pump | Sealed by top quality rotary no-limited machinery seal, no leaking, long lifecycle, small horse power, large flow volume, low noise and high performance. |

| Fan | Axial type;aluminum alloy propeller |

| Casing | SS-304/316L or imported Aluminum-zinc alloy plate, Mg-Al-zinc plate |

| Electric Water Treatment Device | Clear the circuit water, effectively avoid the scale forming on the surface of coils and PVC fills. |

| Removable Drift Eliminator | PVC material; Make sure that the water loss rate will be less than 0.002% |

| Cooling Tower Fill | 100% Original Material PVC Infill, special design with great cooling effect |

FEATURES

◆ Low Maintenance

Unlike most forced draft cooling towers, the GWBB cooling tower utilizes large access doors for easy entry and exit.

◆ Low noise

All cooling towers are made of aluminum alloy axial flow fan, forward-inclined vane structure design, streamlined inlet air duct, small wind resistance, and low noise.

◆ Long Life Construction

Rugged, corrosion-resistant galvanized steel is standard, and the S304 series stainless steel and Magnesium-plated aluminum-zinc plate housing is available as an optional upgrade to the partial or entire cooling tower structure.

ISO certified factories ensure high quality factory assembly.

Delivery

Application

1. Induction heating and metal melting equipment, such as: high and medium frequency quenching equipment, medium frequency power supply and electric furnace, induction diathermy furnace, insulation furnace, etc. cooling.

2. Cooling of circulating water in various reactors and condensers in the chemical industry.

3. Cooling of large motors, diesel engines, rectifier equipment, welding equipment, hydraulic stations and continuous casting equipment.

4. Cooling of metal die casting molds, injection molds and other large molds.

5. Cooling of industrial solution, such as quenching liquid, electroplating liquid, etc.

Advantages of closed cooling tower:

1. The cooling medium is completely closed to prevent debris from entering the cooling pipeline system and the evaporation loss of the cooling medium.

2. Use soft water as cooling medium, no scaling, no clogging of pipelines, and few failures.

3. The dual cooling method of air cooling and spray water evaporation heat absorption is adopted, and the cooling efficiency is high.

4. The device is small in size, takes up little space, and is easy to move and place, without the need to build a pool.

5. Using automatic intelligent control, it can automatically change the cooling mode according to the requirements of working conditions, and the operation is simple and reliable.

6. Widely used, it can directly cool the quenching fluid, oil, alcohol and other media that have no corrosive effect on the heat exchanger. The media has no loss and the composition is stable.

Product case

Hot Tags: cross flow square cooling system, suppliers, manufacturers, customized, price, Dry Cooling Tower pric, Cooling tower in refrigeration system pric, cross flow type cooling tower, Closed Water Cooling Towers, Cross Flow Closed Cooling Tower, Closed Circuit Fluid Cooler