Jiangsu gewabin heat technology Co,.Ltd

Jiangsu gewabin heat technology Co,.Ltd

Closed circuit cooling towers provide evaporative cooling for many types of systems, and the specific application will largely determine which GWB Closed Circuit Cooling Tower is best suited for a project.

Introduction

Closed circuit cooling towers provide evaporative cooling for many types of systems, and the specific application will largely determine which GWB Closed Circuit Cooling Tower is best suited for a project.

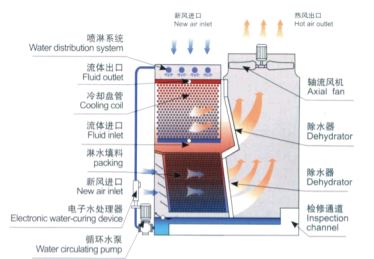

Principle of Operation

Closed circuit cooling towers operate in a manner similar to open cooling towers, except that the heat load to be rejected is transferred from the process fluid (the fluid being cooled) to the ambient air through a heat exchange coil. The coil serves to isolate the process fluid from the outside air, keeping it clean and contaminate free in a closed loop.

During operation, heat is transferred from the internal circuit, through the coil to the spray water, and then to the atmosphere as a portion of the water evaporates.

Product Details

1.Condenser Coil: Made of high-quality seamless steel pipes. The coil unit are galvanized entirely to improve the corrosion resistance ability and extend the service time. The coils can also be made by SS-304/316L stainless steel or T2 red copper. Maximum pressure of our coils could reach to 32Mpa.

2.Spray Pump: Sealed by top quality rotary no-limited machinery seal, no leaking, long lifecycle, small horse power, large flow volume, low noise and high performance.

3.Fan: Aluminum alloy axis-flow type

4.Casing: SS-304 ,imported Aluminum-zinc alloy plate or Magnesium-plated aluminum-zinc plate

5. Removable Drift Eliminator: PVC material; Make sure that the water loss rate will be less than 0.002%.

6.Cooling Tower Fill: 100% Original Material PVC Infill, special design with great cooling effect.

Maintenance

Since the process fluid of a closed loop system is completely isolated from the environment, routine maintenance is only required on the heat rejection equipment itself. The system need to be shut down periodically to clean the heat exchanger, if the heat is not entirely eliminated.

Water Treatment

Maintaining proper process fluid quality in a system may involve several steps, such as chemical treatment, filtration equipment and the addition of clean make-up water.

A closed circuit cooling tower can provide the following advantages over an open cooling tower:

1.Lower volume of recirculating water to treat

2.Process loop requires minimal treatment

3.During periods of dry operation, the need for make-up water is eliminated

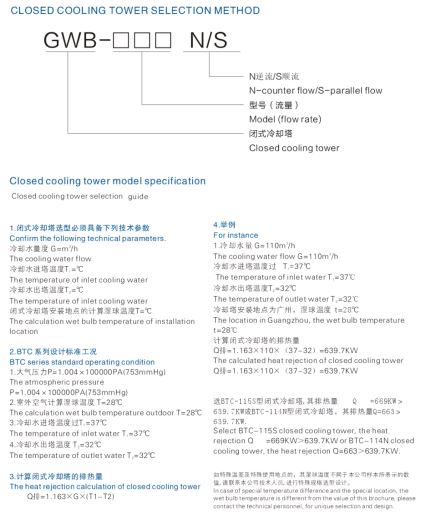

Model Select Guide

Hot Tags: khc closed circuit type cooling tower, suppliers, manufacturers, customized, price, China Dry Cooling Tower, Counter Flow Closed Cooling Tower, Aluminum zinc Plate Closed Cooling Tower, Water Circulating Square Cooling Tower, Cross Flow Closed Loop Cooling Tower, closed cell cooling tower